Chicory root harvesting represents a critical juncture in cultivation that directly impacts both commercial viability and culinary applications. The timing of harvest determines not only the root’s structural integrity but also its inulin content, which reaches peak concentrations during specific physiological phases. Professional growers and home cultivators alike must understand the intricate relationship between seasonal changes, plant maturity indicators, and optimal harvest windows to maximise their yield quality. The difference between a mediocre harvest and an exceptional one often lies in recognising the subtle signs that indicate when Cichorium intybus roots have reached their prime harvesting condition.

Chicory root maturation indicators and peak harvest timing

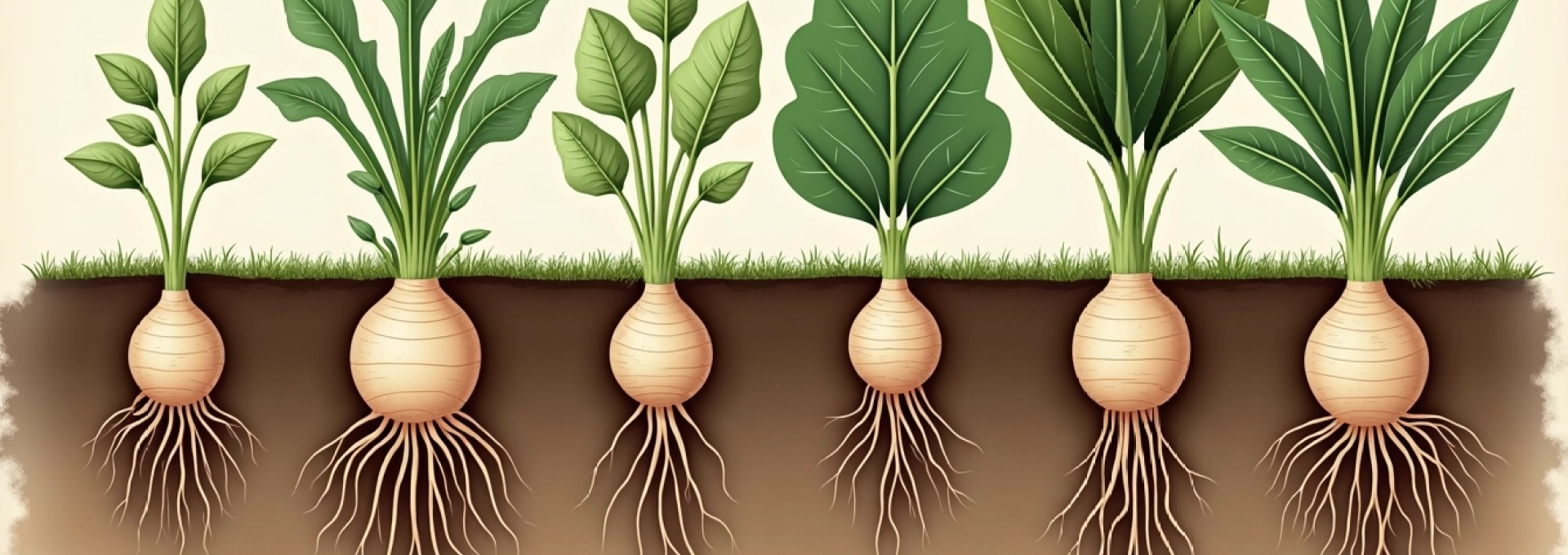

Understanding chicory root maturation requires careful observation of multiple physiological indicators that collectively signal optimal harvest readiness. The plant’s biennial nature means that first-year roots develop differently than those left to mature into their second growing season, with each stage offering distinct harvesting opportunities and challenges.

Cichorium intybus root diameter assessment for commercial harvesting

Commercial chicory operations rely heavily on root diameter measurements to determine harvest timing and grading standards. Mature chicory roots typically achieve diameters ranging from 5 to 7 inches at the crown, with the most valuable specimens reaching this threshold consistently across the field. Root diameter assessment involves measuring at the widest point near the soil surface, where the taproot transitions from the crown. Professional harvesting equipment often includes calibrated measuring tools that allow rapid field assessment without excavating entire plants. The correlation between diameter and overall root quality remains strong, as thicker roots generally contain higher concentrations of stored carbohydrates and demonstrate better storage characteristics post-harvest.

Root diameter varies significantly based on growing conditions, soil composition, and cultivar characteristics. Dense clay soils may restrict lateral expansion, resulting in narrower but potentially longer taproots, whilst sandy loam conditions typically produce the ideal broad, cylindrical shape preferred for commercial applications. Harvesting roots below the 5-inch diameter threshold often results in reduced processing efficiency and lower inulin yields, making diameter assessment a crucial quality control measure.

Taproot length measurement techniques using penetrometer testing

Taproot length evaluation presents unique challenges due to the underground nature of chicory’s primary storage organ. Professional cultivators employ penetrometer testing to estimate root depth without destructive excavation, using soil resistance measurements to identify the typical 9-inch usable portion of mature taproots. This non-invasive assessment technique allows for sampling across fields to determine harvest uniformity and timing. The penetrometer readings correlate with root development patterns, as mature roots create distinct soil density signatures that experienced growers can interpret accurately.

Advanced cultivation operations supplement penetrometer data with selective test excavations, carefully extracting sample plants from representative field sections. These test harvests provide direct measurement opportunities and reveal the actual root length distribution across the growing area. Root length consistency often indicates optimal harvest timing, as mature plants develop relatively uniform taproot dimensions when grown under consistent conditions.

Inulin concentration peaks during autumn dormancy phase

Inulin accumulation in chicory roots follows predictable seasonal patterns that directly influence harvest timing decisions. The highest inulin concentrations typically occur during autumn dormancy, when photosynthesis decreases and the plant redirects energy from leaf production to root storage. Laboratory analysis of root samples reveals that inulin levels can increase by 15-20% during the critical September to November period, making autumn harvest timing essential for applications requiring maximum inulin content.

Root inulin content reaches its absolute peak when soil temperatures consistently remain below 50°F, signalling the plant’s transition into dormancy and triggering maximum carbohydrate storage.

The physiological process behind inulin accumulation involves complex enzymatic reactions that convert simple sugars into the long-chain fructose polymers characteristic of high-quality chicory roots. Temperature fluctuations can interrupt this process, which explains why consistent cool weather produces superior root quality compared to erratic autumn conditions. Monitoring soil temperature alongside visual plant indicators provides the most reliable harvest timing framework for inulin-focused operations.

Foliage senescence patterns as harvest readiness markers

Foliage senescence provides visible indicators of root maturity that experienced growers rely upon for harvest timing decisions. The characteristic yellowing and browning of chicory leaves signals the plant’s natural preparation for dormancy, coinciding with peak root development. Senescence patterns typically begin at leaf tips and progress toward the crown, creating a predictable visual timeline that guides harvest scheduling. Complete foliage dieback indicates that nutrient translocation from leaves to roots has concluded, marking the optimal harvest window for maximum root quality.

Professional observations reveal that premature leaf senescence caused by disease or environmental stress does not correlate with optimal root development, making it essential to distinguish between natural senescence and pathological conditions. Healthy senescence occurs gradually over 2-3 weeks, whilst disease-induced leaf death happens rapidly and often irregularly across the plant canopy. This distinction becomes critical when scheduling large-scale harvesting operations that depend on uniform crop maturity.

Soil temperature thresholds for optimal root sugar content

Soil temperature monitoring provides precise harvest timing guidance that supplements visual plant assessment methods. Research indicates that root sugar content reaches maximum levels when soil temperatures stabilise between 45-50°F at a 6-inch depth, typically occurring during late October to early November in temperate growing regions. Temperature measurements taken consistently at the same time daily create reliable trend data that professional growers use to predict optimal harvest windows with remarkable accuracy.

The relationship between soil temperature and root quality extends beyond simple sugar accumulation to include structural changes that affect processing characteristics. Cooler soil temperatures promote cell wall strengthening and moisture content stabilisation, producing roots that maintain quality during storage and processing. Temperature thresholds vary slightly between cultivars, with witloof varieties typically requiring slightly warmer conditions for optimal development compared to standard root chicory types.

Seasonal chicory root harvesting protocols for maximum inulin yield

Seasonal harvesting protocols must account for regional climate variations, cultivar-specific requirements, and intended end-use applications. The complexity of timing decisions increases significantly when optimising for inulin yield, as multiple environmental and physiological factors converge during the critical harvest period.

Late october to november harvest window for european cultivars

European chicory cultivars demonstrate remarkably consistent harvest timing requirements that align with traditional continental growing seasons. The late October to November window represents the optimal balance between root development completion and pre-winter dormancy establishment. During this period, European varieties typically exhibit 18-22% inulin content by dry weight, significantly higher than roots harvested earlier in the growing season. The extended growing period allows these cultivars to achieve full physiological maturity whilst benefiting from autumn’s cooling temperatures.

Cultivation experience across European growing regions confirms that delaying harvest beyond mid-November risks quality degradation due to freeze-thaw cycles and increased soil moisture content. However, harvesting before late October often results in underdeveloped roots with lower storage quality and reduced inulin concentrations. This relatively narrow harvest window requires careful monitoring and efficient logistics to ensure optimal timing across large cultivation areas.

Post-frost harvesting benefits for witloof and radicchio varieties

Post-frost harvesting offers distinct advantages for witloof and radicchio varieties, as exposure to freezing temperatures triggers physiological changes that improve root quality for forcing applications. The cellular modifications induced by frost exposure enhance the roots’ ability to produce tight, blanched shoots during subsequent forcing procedures. Frost conditioning typically requires 2-3 freeze-thaw cycles to achieve optimal effects, making timing coordination with weather patterns essential for cultivation success.

The post-frost period also coincides with minimal insect activity and reduced disease pressure, creating ideal harvesting conditions that minimise contamination risks. Root handling becomes more manageable as soil moisture typically decreases following frost events, reducing mud adherence and simplifying cleaning procedures. Professional growers often target the first significant frost event as their primary harvest trigger, balancing quality enhancement benefits with practical harvesting considerations.

Frost-conditioned chicory roots demonstrate superior chicon production rates, with forcing success increasing by 25-30% compared to roots harvested before frost exposure.

Spring vs autumn harvesting impact on root quality parameters

Spring harvesting presents an alternative timing option that offers distinct quality characteristics compared to traditional autumn harvest protocols. Spring-harvested roots, collected during March to early April, contain different inulin profiles and moisture content levels that suit specific processing applications. The overwinter storage period in soil creates unique flavour development and textural changes that some culinary applications prefer over autumn-harvested roots.

However, spring harvesting carries increased risks related to weather variability and soil conditions that can complicate harvesting operations. Wet spring conditions often delay field access and create challenging working conditions that impact harvest efficiency. Additionally, spring roots may exhibit more variable quality parameters due to winter weather stress and potential freeze-damage issues. The trade-offs between spring and autumn harvesting require careful evaluation based on intended applications and local growing conditions.

Daylight length correlation with root carbohydrate accumulation

Daylight length directly influences chicory’s carbohydrate accumulation patterns through photoperiod-sensitive physiological processes. As daylight hours decrease during autumn, the plant’s metabolic focus shifts from vegetative growth to root storage, triggering increased inulin synthesis and accumulation. This natural photoperiod response provides a reliable biological clock that guides harvest timing decisions across different geographic locations and growing seasons.

Research demonstrates that carbohydrate accumulation rates accelerate when daylight length drops below 10 hours daily, typically occurring during October in northern temperate regions. The correlation between daylight reduction and root quality improvement remains consistent across multiple growing seasons, making photoperiod monitoring a valuable tool for predicting optimal harvest timing. Professional cultivators often combine daylight measurements with temperature monitoring to create comprehensive harvest timing protocols that maximise root quality consistently.

Pre-harvest chicory root quality assessment methods

Pre-harvest quality assessment requires systematic evaluation techniques that provide accurate predictions of root quality without compromising the overall harvest. Professional assessment methods combine visual inspection protocols with selective sampling procedures that maintain crop integrity whilst providing essential quality data. The assessment process typically begins 2-3 weeks before anticipated harvest dates, allowing sufficient time for timing adjustments based on quality indicators.

Visual assessment focuses on foliage condition, plant uniformity, and growth pattern consistency across the cultivation area. Healthy chicory plants destined for quality root production exhibit dense, vigorous foliage that maintains consistent green coloration until natural senescence begins. Irregular growth patterns or premature leaf yellowing may indicate underlying issues that affect root development and quality. Professional assessors document these observations systematically, creating field maps that guide selective harvesting decisions and quality control measures.

Selective sampling involves extracting representative plants from multiple field locations to evaluate actual root development and quality parameters. Sample extraction requires careful technique to minimise root damage whilst providing accurate assessment data. The sampling protocol typically involves selecting plants from field edges, centres, and intermediate zones to capture quality variation across the growing area. Laboratory analysis of sample roots provides definitive data on inulin content, moisture levels, and structural integrity that guides final harvest timing decisions.

Advanced assessment methods incorporate soil analysis and environmental monitoring data to predict root quality trends and optimal harvest windows. Soil nutrient levels, pH measurements, and moisture content all influence final root quality and must be considered alongside plant-based assessment criteria. The integration of multiple assessment methods creates comprehensive quality prediction models that professional operations rely upon for harvest planning and quality assurance protocols.

Commercial chicory root extraction techniques and equipment

Commercial chicory root extraction demands specialised equipment and systematic procedures that maximise harvest efficiency whilst preserving root quality. The extraction process must account for chicory’s deep taproot system and fragile root structure that can suffer damage from improper handling techniques. Professional operations invest in purpose-built harvesting equipment that addresses these unique challenges through engineered solutions designed specifically for chicory cultivation.

Mechanical root lifter applications for Large-Scale operations

Mechanical root lifters represent the cornerstone technology for large-scale chicory harvesting operations, combining efficiency with quality preservation through sophisticated engineering solutions. Modern root lifters employ adjustable blade systems that cut beneath the taproot whilst simultaneously loosening surrounding soil to minimise root breakage. The equipment typically features conveyor systems that transport lifted roots to collection areas, reducing manual handling and associated damage risks. Professional-grade root lifters can process 2-3 acres per day under optimal conditions, making them essential for commercial viability.

The blade configuration and depth settings require careful adjustment based on soil conditions and root development patterns observed during pre-harvest assessment. Clay soils necessitate deeper cutting angles and increased lifting force, whilst sandy conditions allow for shallower blade positioning that reduces soil disturbance. Operator expertise becomes crucial for optimising equipment performance across varying field conditions and maintaining consistent root quality throughout the harvesting operation.

Hand-digging protocols for premium quality root preservation

Hand-digging protocols remain essential for premium quality root production and selective harvesting applications where mechanical extraction risks are unacceptable. The manual approach allows for individual root assessment and careful extraction that preserves maximum root length and structural integrity. Professional hand-digging requires systematic techniques that balance efficiency with quality preservation, typically involving specialised tools designed specifically for chicory root extraction.

The hand-digging process begins with careful soil removal around each plant using narrow spades or specialised root forks that minimise root contact during excavation. Experienced harvesters work systematically to expose the full root length before attempting extraction, reducing breakage risks associated with premature lifting attempts. The technique requires patience and skill development, as improper handling can reduce individual root value significantly through damage or contamination.

Post-harvest root cleaning and grading standards

Post-harvest processing begins immediately following extraction with systematic cleaning and grading procedures that determine final product quality and market value. Root cleaning involves removing adhered soil, damaged portions, and foreign material whilst preserving the protective skin layer that maintains storage quality. Professional cleaning operations employ rotating brush systems and water wash stations that provide thorough cleaning without causing surface damage that compromises storage life.

Grading standards focus on diameter measurements, length specifications, and structural integrity assessments that determine market classification and pricing. Premium grades typically require minimum 5-inch crown diameters, 8-inch minimum lengths, and absence of significant damage or disease symptoms. Quality control protocols ensure consistent grading standards that maintain market reputation and customer satisfaction across production cycles.

Professional grading operations achieve 90-95% accuracy in quality classification through systematic measurement protocols and experienced personnel training programmes.

Cold storage requirements for extended root viability

Cold storage systems provide essential preservation capabilities that extend chicory root viability from weeks to months, enabling year-round processing and forcing operations. Optimal storage conditions maintain temperatures between 32-35°F with relative humidity levels of 90-95% to prevent moisture loss whilst inhibiting sprouting and decay. Professional storage facilities employ controlled atmosphere systems that regulate oxygen and carbon dioxide levels to further extend storage life and maintain root quality.

Storage preparation involves careful root selection, as damaged or diseased specimens can compromise entire storage batches through contamination spread. Pre-storage treatments may include fungicide applications and careful packaging systems that provide protection whilst allowing necessary air circulation. The storage duration capabilities vary significantly based on initial root quality, storage conditions, and intended end-use applications, with forcing roots typically maintaining viability for 4-6 months under optimal conditions.

Variety-specific harvesting schedules for chicory cultivars

Different chicory cultivars exhibit unique harvesting requirements that reflect their distinct genetic backgrounds and intended applications. Witloof varieties typically require specific harvest timing that optimises their forcing potential, whilst radicchio cultivars focus on leaf production characteristics that influence harvest scheduling. Root chicory varieties bred specifically for inulin production demonstrate different maturation patterns that require tailored harvesting approaches to maximise extraction yields and processing efficiency.

Cultivar-specific scheduling must account for genetic variation in growth rates, environmental sensitivity, and quality development patterns that distinguish individual varieties within the broader chicory species. Professional seed suppliers provide detailed cultivation guides that specify optimal harvest timing for each cultivar, but local growing conditions often require adjustments to these baseline recommendations. Experienced growers develop cultivar-specific expertise through multiple growing seasons that enables precise timing decisions based on variety performance under local conditions.

The integration of variety-specific knowledge with local environmental conditions creates sophisticated harvesting schedules that optimise quality and efficiency across diverse cultivation programmes. Large-scale operations often cultivate multiple varieties with staggered planting dates to extend harvest windows and distribute labour requirements more effectively. This approach requires careful planning and record-keeping systems that track individual variety performance and harvest outcomes across multiple seasons.

Advanced cultivation programmes may incorporate breeding selection criteria that favour varieties with extended or flexible harvest windows, reducing timing pressure and increasing operational flexibility. The development of new cultivars continues to focus on improving harvest timing

tolerance that reduces harvest timing constraints and improves commercial viability for diverse growing operations.

The economic considerations of variety-specific harvesting extend beyond simple timing adjustments to encompass labour allocation, equipment utilisation, and market coordination requirements. Varieties with concentrated harvest periods may command premium pricing due to quality consistency, whilst those offering extended harvest windows provide operational flexibility that reduces labour costs and equipment requirements. Professional operations must balance these competing factors when selecting varieties and developing cultivation strategies that optimise both quality and profitability across diverse market conditions.

Regional adaptation of chicory varieties creates additional complexity in harvesting schedule development, as varieties developed for specific climatic conditions may perform differently when grown outside their optimal zones. Northern European varieties typically require longer growing seasons and later harvest timing when cultivated in southern regions, whilst Mediterranean-adapted cultivars may mature earlier than expected in cooler climates. This geographic variability necessitates local testing programmes that establish variety-specific performance data for individual growing regions and microclimatic conditions.

Modern cultivation programmes increasingly rely on data-driven variety selection processes that incorporate harvest timing flexibility as a primary selection criterion alongside traditional quality and yield parameters. The development of precision agriculture techniques enables detailed tracking of variety performance across multiple parameters, creating comprehensive databases that guide future variety selection and harvesting schedule optimisation. These advanced approaches represent the evolution of chicory cultivation from traditional methods toward science-based production systems that maximise both quality and operational efficiency.

Professional chicory operations report that variety-specific harvesting schedules can improve overall harvest efficiency by 20-30% whilst maintaining or improving root quality parameters across diverse growing conditions.

The implementation of variety-specific schedules requires sophisticated planning systems that coordinate planting dates, cultural practices, and harvest logistics to ensure optimal timing for each cultivar within the production system. This complexity increases significantly in operations cultivating multiple varieties simultaneously, requiring detailed record-keeping and monitoring systems that track individual variety progress throughout the growing season. The investment in variety-specific management systems typically generates returns through improved quality consistency and reduced harvest losses that result from improper timing decisions.

Future developments in chicory variety breeding continue to focus on harvest timing optimisation through genetic improvements that extend harvest windows, improve environmental stress tolerance, and enhance storage characteristics. These breeding objectives reflect the commercial reality that harvest timing constraints represent significant operational challenges for professional growers seeking to maximise quality whilst maintaining economic viability. The successful integration of improved varieties with optimised harvesting schedules represents the continuing evolution of commercial chicory production toward more sustainable and profitable cultivation systems.